Technology

- Construction Equipment Manufacturers requiring improved durability.

- Aerial Lift Manufacturers needing smooth, dependable hydraulic cylinder operation.

- Infrastructures and bridges with dampers can prevent damages or any structural failure caused by vibration during earthquakes.

- Mining Equipment Manufacturers wanting hydraulic cylinders to last in the harshest environments.

- Emergency Vehicle Manufacturers requiring unmatched reliability.

- Material Handling Manufacturers who need product and delivery flexibility.

- On-Highway Equipment Manufacturers requiring improved product integrity.

- OEM Manufacturers needing on-time reliability, high quality and superior value.

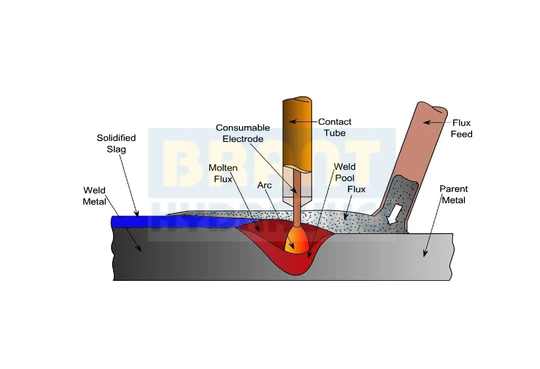

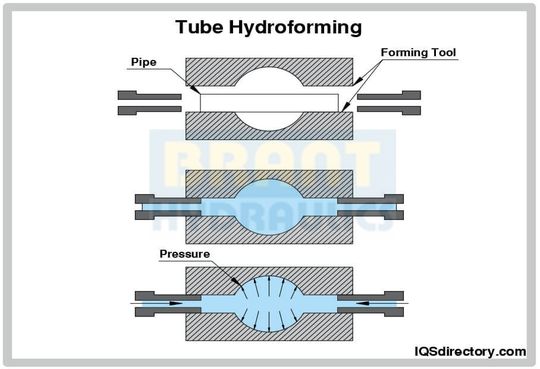

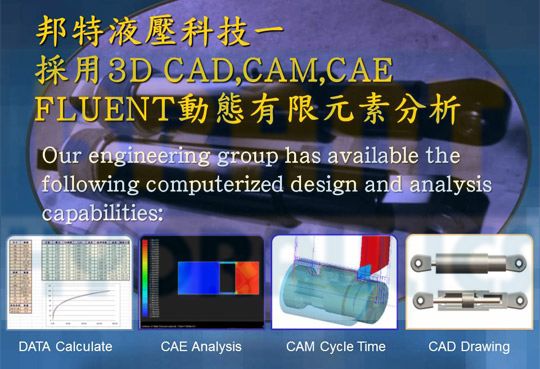

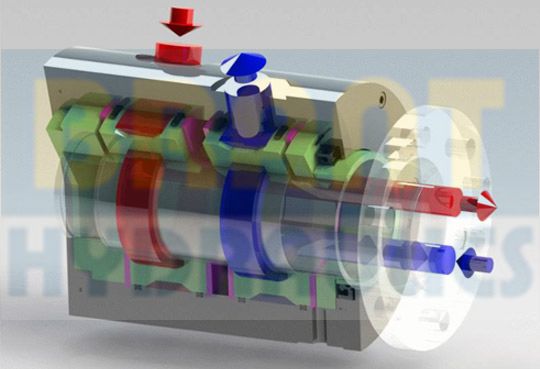

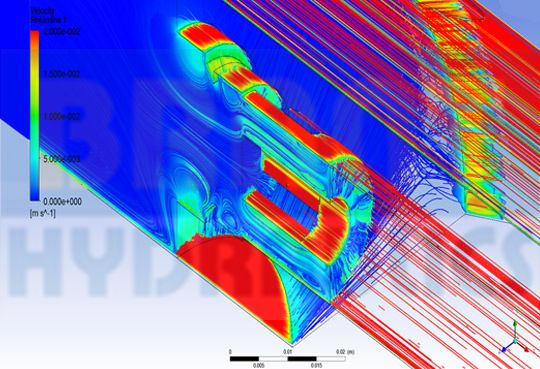

We design and manufacture both double-acting and single-acting custom hydraulic cylinders up to 1500mm bores with stroke lengths up to 10m. Typical operating pressures range from 100 to 500 bars. Brant Hydraulics' design and manufacturing expertise in custom hydraulic cylinders allows the integration of valves, valve manifolds, internal and external hydraulic tubing, unique fluid connections, application specific cushions, as well as, mounting configurations for the specific application. Unique products, such as, hollow rod hydraulic cylinders, piggy-back hydraulic cylinders, double rod-ended hydraulic cylinders are regularly produced at all locations. Hydraulic swivels are also available.

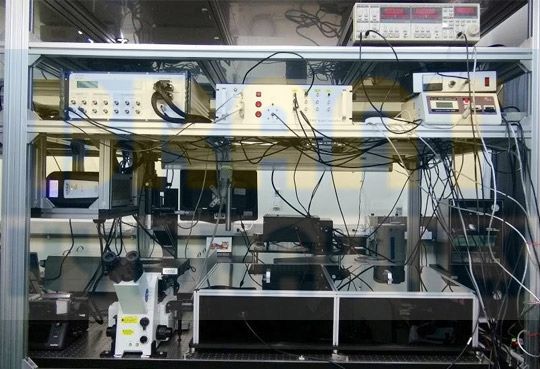

Brant manufactures all types of hydraulic cylinders to meet our customers' needs, including cylinders with electronic "position feedback" devices. These devices are required for many control circuits or monitoring systems. We routinely modify our hydraulic cylinders to accept various devices. This includes, but is not limited to, Balluff and Gemco systems.

Designed especially for our high-performance hydraulic cylinders and dampers, Brant accessories enable you to get maximum performance from your solution. And because they are built to the same standards as our other products, you know they're built to last for a long time.