Quality Assurance

Special Constructions

Due to our flexibility, we are in a position to go along with specific requests and demands from our customers to a large extent. Custom-made solutions are our daily business which ensures that for any requirement the right equipment is used. All solutions are optimised individually and tailored to our customer's specifications and specific application cases.

The mutual development of the right solution guarantees our customer an efficient fulfilment of his demands. We also manufacture to customer's drawings, if available.

Repairs

Take advantage of our experiences in the fields of repair, maintenance and servicing. We repair and/or maintain your hydraulic or dampers components, irrespectively of make and type, within shortest time. Immediately on receipt of the respective components at our premises we will work out a detailed offer for the repair/maintenance work - which under normal circumstances is free of charge - and, if necessary, with exact damage analysis. After customer's approval the repair and/or maintenance work is executed within a few days - and if required and possible - even within some hours.

On request we do not only exchange parts but also optimise the hydraulic cylinders and dampers in cooperation with the customer. Such measurements may partly lead to considerably higher stand still times which increase the service live of the machines and reduce the costs.

Quality Assurance

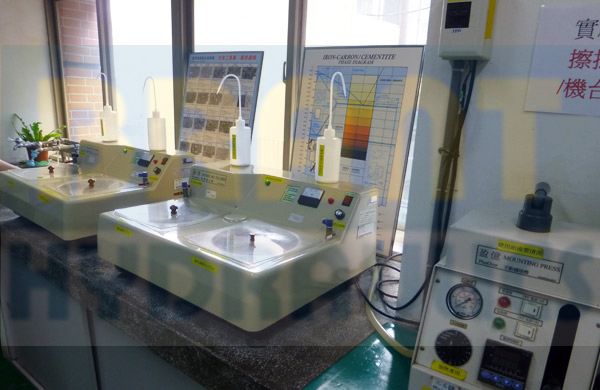

Our quality control is based on ISO 9001 to design and implement; as the result, we have the quality plan. Based on the quality plan, we execute the quality control operations which include material testing reports, dimension inspection reports and function test reports. The above procedure enables the buyers to monitor us easily and to minimize the time and money on monitoring. To achieve the goal of real cost down, we offer quality products with low prices; plus there is no quality control budget needed from our customers.

Each product of the Brant Hydraulics represents the ideal synthesis of most modern technology, thorough execution and decades of experiences. The demands on such high-quality products are high, the reliability has set upper limits world wide. In order to achieve and maintain such a high quality level continuously, Brant Hydraulics uses state-of-the-art methods and devices.