Mining Hydraulic Cylinders

Brant Hydraulics' hydraulic cylinders for mining industry are designed to handle high pressure and provide strong pushing and pulling power. They are used for different tasks like building tunnels, digging at construction sites, making holes, and drilling.

Not only we could manufacture all kinds of mining cylinders according to the drawing from our customers, but also we could make a design according to customer's requirements.

Some of the common mining machines used in various types of mining operations:

- Excavators

- Bulldozers

- Dump Trucks

- Drills

- Loaders

- Haul Trucks

- Shovels

- Continuous Miners

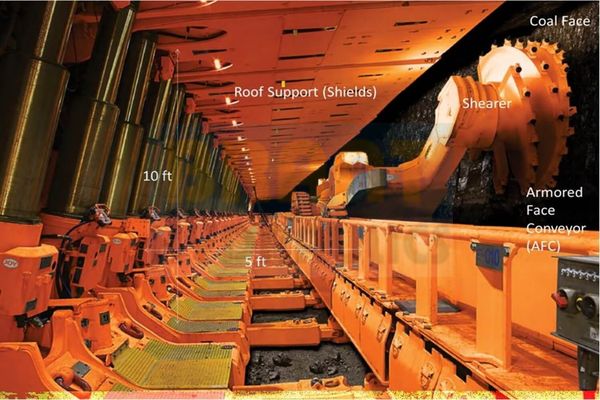

- Longwall Miners

- Draglines

- Screening Machines

- Crushers

- Conveyors

- Graders

- Rock Bolters

- Boring Machines

- Slurry Pumps

- Suction Dredgers

- Hydraulic Mining Machines

- Cutting Machines

These machines are essential for various mining processes, including surface and underground mining.

In underground mining, hydraulic cylinders play a vital role in roof support systems. These systems use hydraulic cylinders to control and stabilize the roof in underground tunnels and galleries, ensuring the safety of miners and preventing cave-ins. By exerting pressure against the mine roof, hydraulic cylinders provide essential structural support, minimizing the risk of accidents and maintaining stable working environments.

Visit other Construction Vehicle Cylinders, Construction Cylinders, and Telescopic (Long Stroke) Cylinders

Contact us or email us for any other inquiries.