Lead Rubber Bearing

Lead Rubber Bearing – Excellent in Absorb Energy Dissipation and Seismic Isolation

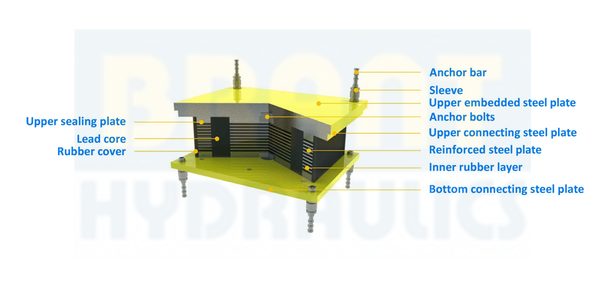

Lead rubber bearing, also called lead core rubber bearing, LNR rubber bearing, has similar structure with high damping rubber bearing. It is an important component of seismic isolation bearing. It is composed of laminated rubber bearing and lead core. The lead core can not only bear the heavy load and horizontal force, but also absorb energy through plastic deformation of hysteresis damping.

Lead rubber bearing can be divided into round and rectangular shapes for different application. Additional, the lead core quantity can be single or multiple to supply maximum flexibility in the bridges or building.

The lead rubber bearing has same mechanical properties with laminated rubber bearing. Besides, it has high damping property.

As we all know, the laminated rubber bearing has large displacement deformation in horizontal direction.

In the earthquake, this structure can separate top and bottom structure vibration, enlarge self vibration cycle and reduce seismic force. Besides, the lead core will be squeezed and yielded during the shear process to dissipate Seismic force.

After the earthquake, the lead rubber bearing can help building restore the normal position through dynamic recovery and recrystallization of lead core and shear strain of laminated rubber bearing.

- Vertical loading transfer process: beam → top embedded steel plate → top connecting steel plate → top sealing steel plate → laminated rubber bearing with lead core structure → bottom sealing steel plate → bottom connecting steel plate → pier.

- Horizontal loading transfer process: pier → bottom anchor bolts → bottom connecting steel plate → top sealing steel plate and shear tenon → top connecting steel plate → top embedded steel plate → anchoring components.

Function of lead core bearing pad

- Top and bottom plates: transfer loading and constraint deformation of lead core.

- Lead plug: dissipate energy and decrease displacement.

- Steel reinforcing plates: increase vertical stiffness and constraint deformation of lead core.

- Internal rubber layers: support structure weight, accommodate rotation and displacement, recovery moving bearing to the original position.

- Rubber cover: protect reinforced steel plates and rubber layers.

Specification

- Shear modulus: 0.8 MPa, 1.0 MPa, 1.2 MPa.

- Working temperature range: -25 °C to +60 °C.

- Lead core quantity: single or multiple.

- Shape: rectangular and round.

-

Technical parameter

- Rectangular lead rubber bearing specifications.

- Round lead rubber bearing specifications.

Production & Package

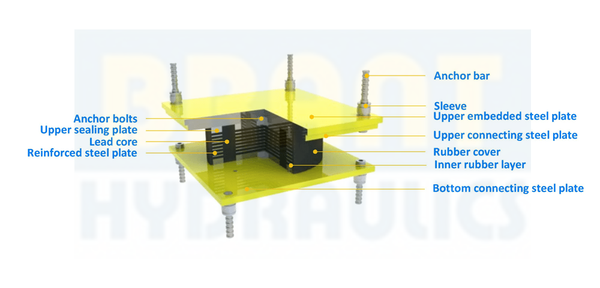

- Vulcanize the rubber and reinforced steel plate together to form the laminated rubber bearing. During this process, the lead core position should be reserved in advance.

- Press the lead core into reserved positions and vulcanize them together.

- Vulcanize the top and bottom sealing steel plate.

- Connect the top and bottom connecting steel plate with anchor bolts.

- Pack the lead rubber bearing with plastic films.

Features

- Stable vertical stiffness and excellent vertical loading capacity.

- Suitable horizontal stiffness. Satisfy the earthquake vibration and normal displacement. It can enlarge the vibration cycle to 1.5 to 3 seconds.

- Excellent damping performance.

- Good energy dissipation capacity.

- Adjustable lead core area. It can suit different damping ratio through adjusting wire diameter and sectional area.

- Excellent durability, cycle fatigue resistance, acid and alkali resistance.

- Long lifespan. 60–80 years long lifespan for durability.

- Easy installation and replacement for lower maintenance costs.

Application

Lead rubber bearing, main branch of seismic isolation system, is widely applied to the large sized structures such as road bridges, rail bridges and nuclear power station to minimize damages from dynamic loads like earthquake.

We do have many other types of dampers products available.

Please Contact us or Email us for more details.