Equipment

State-of-the-art industrial facilities

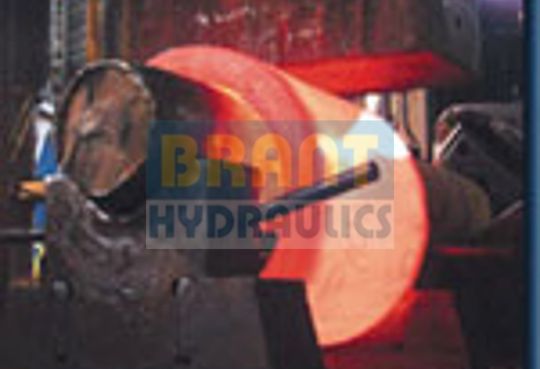

Brant Hydraulics excels in technical expertise, in fields such as custom designed dampers, hydraulic cylinders, extra-large hydraulic cylinders, heavy duty, very high-speed or zero-leakage technology cylinders. Our means of production are particularly impressive, with gantry and portal milling machines, large grinding machine, vertical honing, polishing machines, welding machines etc. Most of our machines are digitally computerized (CNC).

Brant Hydraulics can design any type of custom designed hydraulic cylinders and dampers, per the customer's requirements, as long as it fits in our wide manufacturing capabilities, which are below :

| Metric | Inches / Feet | |

|---|---|---|

| Bore diameter (I.D.) | Up to 2 500 mm | Up to 100 inches |

| External diameter (O.D.) | Up to 3 000 mm | Up to 120 inches |

| Length | Up to 25 000 mm | Up to 1000 inches |

| Turning & Boring | Up to 2 500 mm / 100 inches external diameter Up to 25 000 mm / 1000 inches in length |

|---|---|

|

Honing (vertical / horizontal / roller burnishing) |

Up to 2 500 mm / 100 inches inside diameter Up to 25 000 mm / 1000 inches in length |

|

Milling & Drilling (machining center) |

Up to 17 230 mm / 680 inches in length Up to 5 060 mm / 200 inches in high Up to 2 350 mm / 95 inches wide |

| Grinding | Up to 2500 mm diameter 100 inches Up to 16 000 mm / 630 inches in length |

| Polishing | Up to 2 500 mm diameter / 100 inches Up to 25 000 mm / 1000 inches in length |

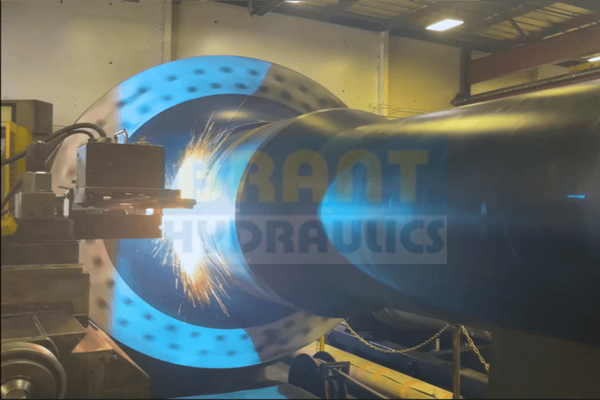

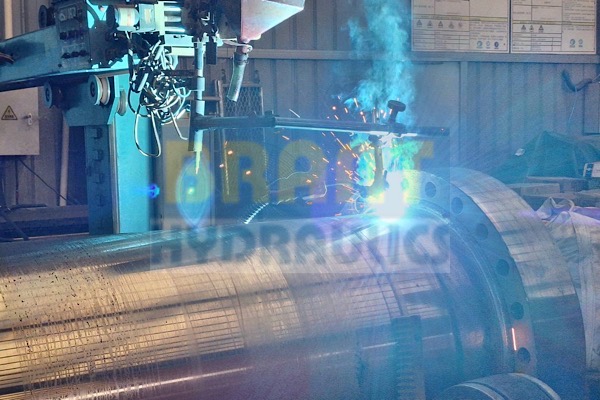

| Welding | TIG / GTAW (Gas Tungsten Arc Welding), MIG / GMAW (Gas Metal Arc Welding), SAW (Submerged Arc Welding) |

Maximum crane overhead lifting capacity: 60 Tons

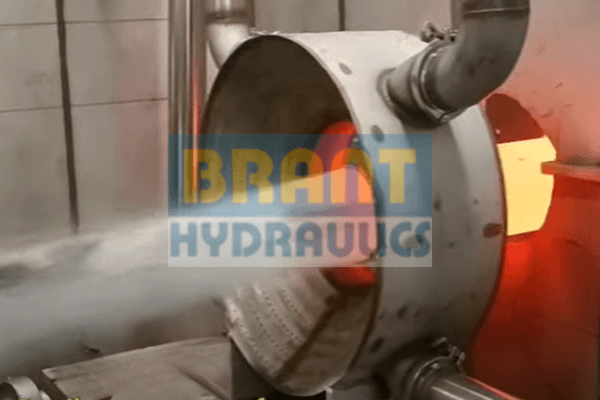

Test Bench

Brant Hydraulics received an ISO 17025 Laboratory Certification certified by the world recognized International Laboratory Accreditation Cooperation. Putting them to the forefront among hydraulic cylinder and dampers producers.

Honing Machine (Skiving & Roller Burnishing)

Brant has high efficient and accurate Honing machine facilities to provide machining from 20mm to 2,000mm in diameter and over 12,000mm in length. These advanced machines also supply to the customers who need this service particularly.

Various kinds of Large Lathe

Brant's large lathes can manufacture various kinds of hydraulic cylinders and dampers because they have maximum swiveling radius from standard size to 1500mm and over 10M in length.

General Kinds of Lathe

Brant utilizes different kinds of precise lathe equipment to undertake all kinds of lathe processing works with several fixtures and tools to process the spare parts of hydraulic cylinder and dampers.

Grinding Machine

Brant applies various kinds of grinding machines which can grind the different sizes of hydraulic cylinder rod and dampers from standard diameter up to 1500mm and its length can be over 10m.

Machining Center

To produce special shape of hydraulic cylinder, damper, and machinery, Brant owns #3-50-#6 centralized machining equipment with wide range of processing technique and accuracy rate.

CNC Lathe

Brant has wide range size of CNC lathe, from #2 to #7. With such high technical equipment, Brant is doubtless to mass-produce various kinds of components of hydraulic cylinder and damper with top quality.