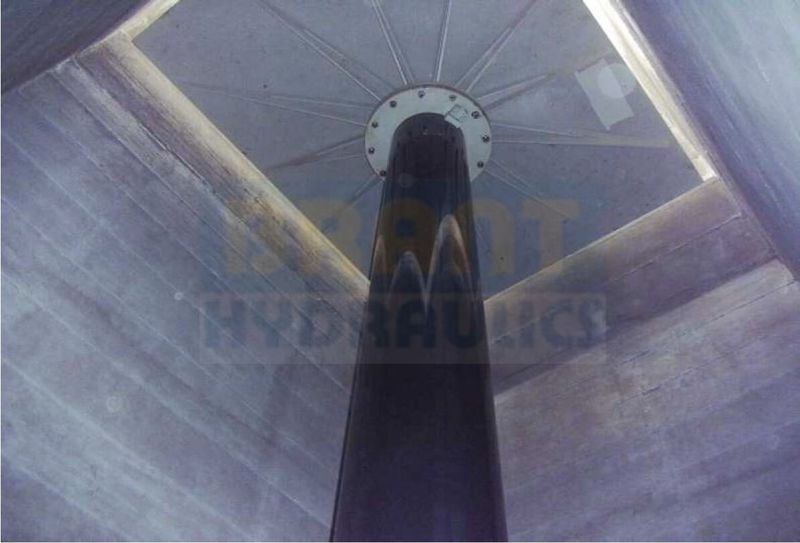

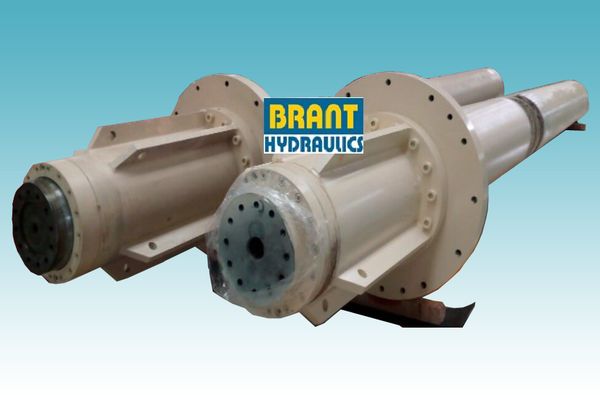

Our cement hydraulic cylinders application include cement process such as vertical grinding mills, crushers, rotary kiln, and more. In the systems used during cement grinding and instant cement cooling in the clinker cooling system, the processes are implemented by the help of hydraulic cylinders. This kind of cylinders have been manufactured and maintained by Brant Hydraulics for years and safely installed in the facilities.

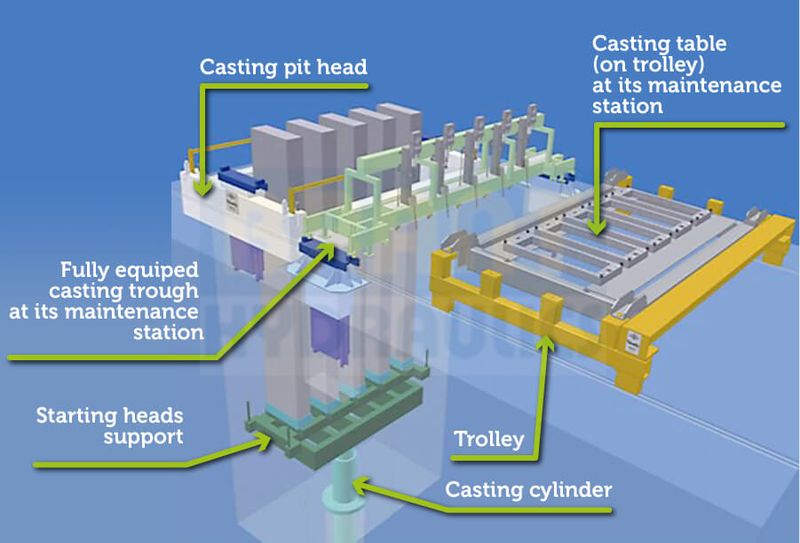

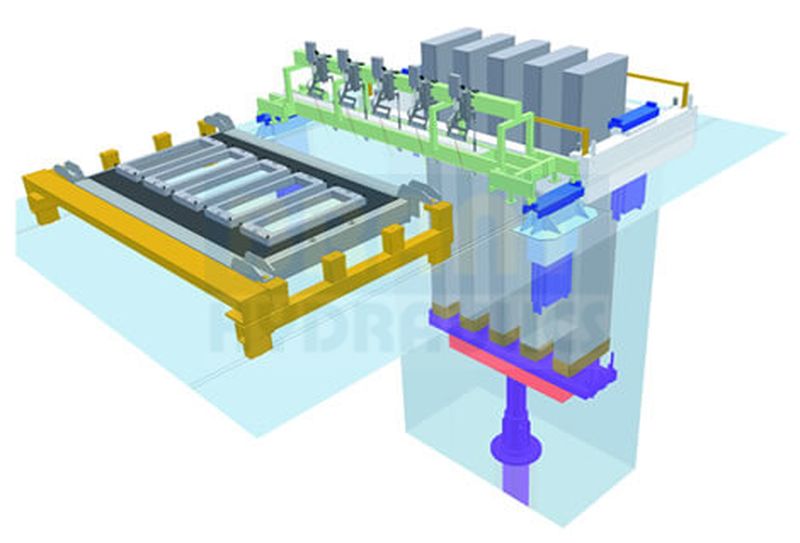

During cement production, the raw material reaches a temperature of around 1450 ° C in the kiln. The clinker grains that are initially sent from the kiln to the isokinetic inlet are cooled down to 65 ° C + ambient temperature in the cooling equipment operating with the instant cooling principle. The reason why the cooling equipment works with the instant cooling principle is to provide the appropriate phase composition of the clinker processed between different temperatures. Besides, the instant cooling process is also crucial in maximizing the recovery of heat to secondary air and tertiary air. The cold air needed by the cooling equipment to perform the instant cooling process is regained to the system by a certain number of fans under the clinker bed with the help of compressed air.

We had been doing the hydraulic cylinders since 1995, we have experienced staff and we served many world famous cement mills. We use Germany Rexroth Technology, The rod we can plate hard chrome, nickel or Ceramic. The seals we use the original seal kits: NOK, Merkel, Parker, Trelleborg, and more. No matter what your need is for hydraulic cylinders, like honing, CNC, boring, lathe, cutting, welding, sand blast, painting, we can do it.

Don't hesitate to contact us if you have any inquiry about cement application or cement products!